Electroplating process management is an important link during production. It is determined by electroplating workers after millions of times of trial and research. So electroplating process has a strong scientificity. The determination of the process should not only take into deposition rate of coating, current efficiency of anode and cathode, the dissolution of metal ions and depositional balance, but also consider stability of PH value, temperature, broadness of current density, rate of bright dipping, leveling performance, light range and other factors. Therefore, we must pay attention to all specified technical specifications. On this basis a good coating can be plated. Regarding how to strengthen the management of the electroplating process, we put forward the following views:

Process management

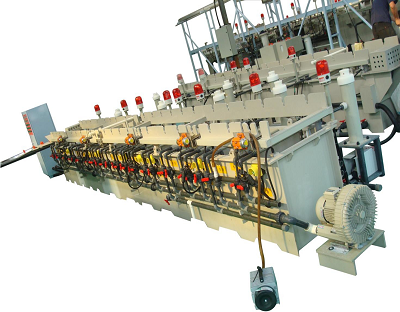

Pre treatment

Electroplating pre treatment is the basis of electroplating quality. If the pre- treatment is not good, the plating layer is either blooming, bubbles, shelling, or even both, resulting in scrapped products. The pre-treatment of electroplating is mainly to remove oil stains, oxide scale, rust, etc. on the workpiece. This not only guarantees the good bonding force between the substrate and the plating layer, but also accelerates the deposition rate of the plating layer, and at the same time ensures that the plating solution is not contaminated by the oil stains and foreign metal impurities of the plating parts.

For example, there is a manufacturer of zinc plating, after zinc plating they found that on the layer had serious blister and burr, so they adjusted plating solution repeatedly, but the problem couldn’t be solved. Later an old master found that before putting workpiece into plating bath there was a glue-like substance sticking to the surface. It turned out that glue, which was in the container of sulfuric acid dissolved and stuck to the surface of workpiece. So we suggest that for pre-treatment must carry out degreasing, rust removal according to process stipulation and observe workpiece’s surface states. The plating pre-treatment includes ultrasonic degreasing, chemical degreasing, electrolytic degreasing of anode and cathode, acid rinsing to remove the oxide scale, corrosion and etc. Should regularly analyze the composition of derusting solution, regularly add solution, filter alkali bath. The acid tank should be regularly discharged, updated, etc. In order to guarantee quality of plating layers, should make oil removal solution and rust removal solution in good condition.

Testing and management of component of plating solution

Laboratory analysis

Regularly test the content of solution component and timely adjust is a scientific management method. The scale of the test can be large or small. For a pure plating manufacturer, it only needs to be equipped with some simple test equipment and a small amount of investment. The personnel can be part-time and can operate after training.

Method of specific gravity

Measured with Baume specific gravity method. This method is only suitable for solutions with relatively simple bath composition. For example, chromium plating is dominated by chromic acid, and sulfuric acid accounts for only about 1%, which can be ignored. This method is also applicable to pre-treatment acid (hydrochloric acid or sulfuric acid), as well as the activated acid of each channel, and the Baume degree can also be used as a reference.

Explore the rules and accumulate experience

Take the method of add small amount per time and add frequently, gradually explore the law of consumption and bring out the loss to supplement, make the ingredients relatively stable, and accumulate certain experience. But this method is certainly not scientific enough, it is mainly controlled by experience.

Attentions in process management

- In order to manage process, besides carefully control component content, also need pay attention to water quality of bath and avoid to wrongly add chemical materials. Ever we met the situation of adding thiourea into nickel plating bath when mistaking thiourea for boric acid. It blackened the plating layers. It didn’t return to normal until added more hydrogen peroxidde and activated carbon and processed. Therefore, we suggest that when add chemical materials into plating solution, should follow three steps “looking, testing and adding”to avoid loss.

In the bright acid copper solution, the chloride ion can be removed by the silver salt method, that is, the calculated amount of silver nitrate (removing 1 part of chloride requires 5 parts of silver nitrate) is dissolved in distilled water, and then the sodium carbonate is dissolved in distilled water, and the sodium carbonate is mixed under stirring. The solution was gradually added to the silver nitrate solution to make it alkaline to stop, and then rinsed with distilled water several times, the precipitate was silver carbonate.

Add to the acid copper solution under stirring, Ag2CO3+2HCl=2AgCl+H2O+CO2. Just after filtering. This method is very good, but the cost is expensive, so it is not used much in production. The zinc powder method can also be used to remove chlorine, which has a lower cost, but you must pay attention to the treatment methods. First use analytically pure zinc powder 1~3gL to make a paste with water, add it to the acid copper solution under gradual stirring, after adding it and let it stand for 0.5h (the acid copper solution does not need to be heated), add powdered activated carbon 1.5~2.0 gL, stir evenly, stand for 0.5~1.0h, and filter. The author told this method to a unit that added hydrochloric acid by mistake, and the other was a unit that used township tap water to prepare tanks. The result of the former was good, and the latter had no effect due to the precipitation overnight and then filtering.

- In order to ensure the stability of the plating solution, beware of foreign metal impurities being brought into the plating solution. The author recommends that the nickel-plated products on copper, the nickel plating solution must be regularly electrolyzed with a corrugated iron plate with a current density of about 0.05 Am2, otherwise a copper removal agent must be added to ensure the brightness of the small current density area. In addition, if the parts fall into the nickel plating tank or acid copper plating tank, they must be removed in time to prevent the accumulation of impurities.For copper parts and zinc alloy workpieces falling, it is recommended to use window screens to make flat screens slightly wider than the bottom of the groove, and to tie up the four corners with plastic tubes (rods). Pick up the four plastic rods at the end of get off work. The zinc alloy parts are taken out to avoid or reduce the accumulation of copper and zinc impurities in the nickel plating solution, thereby reducing the failure of the plating solution.

- Incomplete insulation or bubbling of the hanger makes the chromium plating solution unclean, causing the chromium plating solution to be carried into the cyanide copper plating solution or nickel plating solution, contaminating the plating solution and causing malfunctions. Therefore, it is required that the insulation of the hanger must be intact. For the hanger that hangs to the end on the automatic line, take the chromium back and then hang the workpiece to avoid chromium contamination of the plating solution.

Operating conditions

Temperature and current density

In actual operation, it is necessary to choose the best temperature, which is extremely important to the quality and stability of electroplating. It is necessary to filter out the best temperature according to various workpieces and strictly control it. This is an important measure to ensure quality. Temperature and cathode current density are generally proportional. The temperature is high (within the process range), the cathode current density can be opened up, the coating is fine, and the deposition rate is fast.

Conductive contact

Conductive contact generally refers to the contact between the hanger and the pole, the contact between the anode hook and the pole, the contact between the pole and the copper ingot, the contact between the copper bar and the copper ingot, etc., each conductive contact point needs to maintain the color of copper, so This reduces the resistance or reduces non-conductivity due to poor local contact, which affects the quality of the plated parts. The author suggests that the conductive contact parts should be brushed frequently and kept clean.

Cathode movement and stirring

The purpose of cathode movement and stirring is to accelerate the convective diffusion of ions, increase the current density of the cathode, and at the same time improve the uniformity of the coating, and the hydrogen is easy to precipitate. If the cathode movement stroke or frequency does not meet the requirements, air tumors or streaks are likely to occur when plating large flat workpieces. The stroke of the cathode movement must be controlled at about 10cm, and the frequency is 15 minutes. In addition to the above effects, air stirring can also reduce the production of monovalent copper for bright acid copper liquid, but air stirring must be matched with continuous filtration. Its continuous filtration is not less than 5-10 cycles per hour, otherwise it is easy to produce burrs.

Quality Control

Electroplating enterprises must implement modern quality management. To do a good job in quality management, first of all, we must establish a quality management system in accordance with the GBT19000-ISO9000 quality management standard. To this end, it is necessary to establish electroplating quality standards, including the establishment of quality requirements between various processes, such as sanding, degreasing, and acid etching. At the same time, it is necessary to establish a corresponding inspection system, such as finished product inspection methods, which are inspections one by one. Or sampling inspection and so on. Formulate standards and strengthen inspections to prevent unqualified plating parts from leaving the factory, so that unqualified plating parts between processes do not flow into the next process, blocking the occurrence of batch defective products, and eliminating defective products in the production process, so as to ensure Quality, improve the rate of genuine products.

Therefore, we suggest to strengthen the basic work of modern quality management.

Pay attention to the quality of raw materials

When companies purchase metals and chemical raw materials, they pay more attention to their quality while paying attention to prices. We believe that price and quality must be considered. If only the price is considered, it will cause unstable plating solution, many failures, and finally the plating company will suffer. For example, some zinc ingots are of poor quality, lead impurities, etc. exceed the standard, coating quality is unstable, and failures are frequent. We believe that not only the price factor must be considered when purchasing raw materials, but also the importance of raw material quality. Price and quality should not be neglected. Only by grasping the quality of raw materials and equipped with a set of modern quality management system can enterprises have good economic benefits.

Oct. 29, 2020

Oct. 29, 2020