The heating roller adopted good performance silica gel materials, it's fit for laminating both soft and hard plate.

The laminating speed can be adjusted

Controlled surface temperature to laminated roller accurately

The width has wide range and could customized by your need

Used for single side and double sides

Good viscosity strength and no bubble

High strength and heat evenly

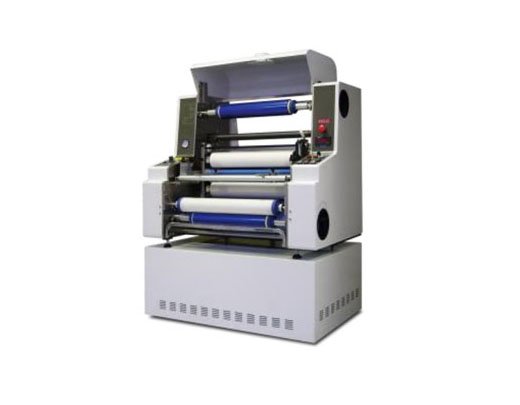

Product Description

Control system:

Auto temperature control system

Speed adjust system

Features:

The heating roller adopted good performance silica gel materials, it’s fit for laminating both soft and hard plate.

The laminating speed can be adjusted

Controlled surface temperature to laminated roller accurately

The width has wide range and could customized by your need

Used for single side and double sides used

Good viscosity strength and no bubble

High strength and heat evenly

Timely service, one year warranty, life-long maintenance

Provide free training for customers in any places.

Applications:

Dry Photoresist laminator for dry film resist laminate use. Mainly used in hardware, circuit board and metal etching products photosensitive plastic coating processes.

Specification

|

No. |

Item |

Specification |

|

1 |

power supply |

AC220V 1φ 50 / 60HZ 6KVA |

|

2 |

Dimensions |

L 1190 x W 746 x H 1118 (mm) |

|

3 |

Substrate size |

Length: 240 ~ 610 m / m |

|

Width: 250 ~ 640 m / m |

||

|

Thickness: 0.1 ~ 3.0 m / m |

||

|

4 |

Dry Film size |

Film width: 250 ~ 640 m / m |

|

Film thickness: 15 ~ 76μm |

||

|

Film diameter: 500ft / 1000ft |

||

|

5 |

Load section |

Roller: aluminum material φ 31.5 m / m, P = 76 m / m |

|

6 |

Film laminating section |

Hot Wheel: φ 80 m / mx 760 m / m, the electric power 1.5KW (about 19 KG) |

|

The conveyance speed: 2 ~ 4 M / MIN, adjustable |

||

|

Pressing roll temperature: room temperature ~ 120 ℃ |

||

|

Temperature control: PID type, SSR drive |

||

|

Pressure of Hot roll: AIR pressure 2 ~ 5 KG / cm2 |

||

|

7 |

Unload section |

Roller: aluminum material φ31.5m / m P = 76m / m |

|

Structure: a main body fixed, manual load and unload |

||

|

8 |

Feature |

Fine adjustment film deviation without stopping the operation |

|

9 |

With |

Adopt inductive magnetic wave heating. |

Looking forward to providing you with satisfactory products and services.

info@everest-machinery.com