Main structure and precautions of UV exposure machine

Sep. 14, 2021

Sep. 14, 2021

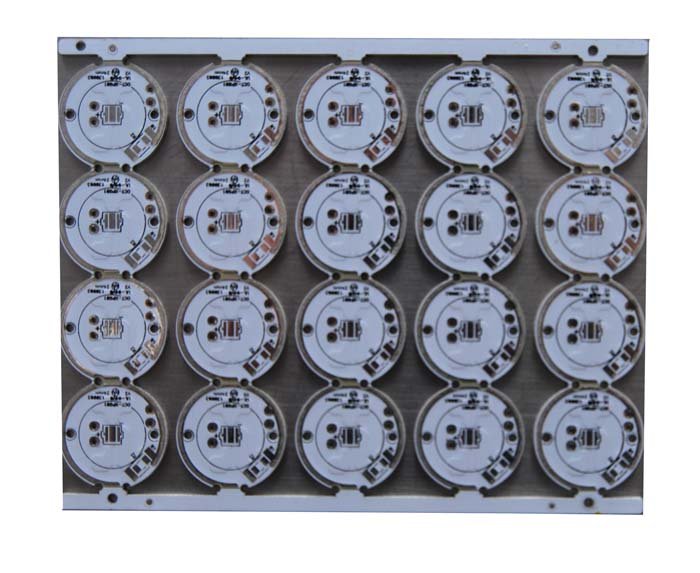

UV exposure machine is an essential equipment for modern PCB manufacturing. In the PCB manufacturing process, one of the most key processes is to transfer the negative image to the copper foil substrate. First, a layer of photosensitive material (such as liquid photosensitive adhesive, photosensitive resist dry film, etc.) is coated on the substrate, and then the photosensitive material coated on the substrate is irradiated to change its solubility. The resin of the non photosensitive part is not polymerized and dissolved under the action of the developer, and the resin of the photosensitive part remains on the substrate to form an image. This process is exposure, That is, the process completed by the exposure machine in the production of printed circuit board.

Sep. 24, 2021

Sep. 24, 2021