Do you know what is the surface treatment of PCB? And what is the HASL?

Aug. 13, 2021

Aug. 13, 2021

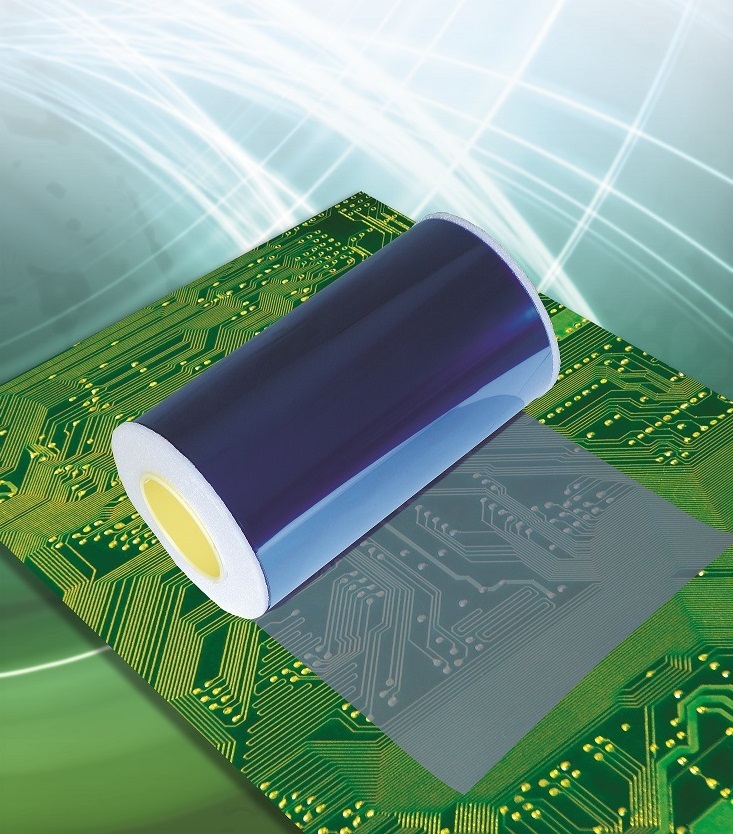

Introduction to PCB surface treatment process The most basic purpose of PCB surface treatment is to ensure good solderability or electrical properties. Since copper is easily oxidized in the air, and the copper oxide layer has a great influence on welding, if the copper layer is oxidized, it is easy to cause false soldering and virtual soldering. In severe cases, the pads and components cannot be soldered. Although a strong flux can be used to remove most of the copper oxide, the residue of the strong flux itself can also cause corrosion to the product. Therefore, the common processing method in the industry is to add a process during PCB production, that is, coating (plating) a layer of material on the surface of the pad to protect the pad from oxidation.