With the development of technology and the continuous upgrading of electronic products, single-sided and double-sided PCBs have gradually been unable to meet the growing demand for products. At present, with regard to the manufacture of high-level multi-layer PCBs, the lamination method is the most typical manufacturing process, and the lamination process is the soul of the lamination process.

What is the bonding process ?

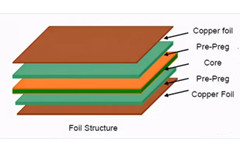

In the manufacture of PCB, the lamination process usually refers to the lamination of copper foil, prepreg and the core board (inner layer) with a prepared circuit in a certain order, and then through a press, first hot pressing, under high temperature and high pressure conditions. , fuse it into one, and then cold-press to release the stress and ensure the product is flat.

Among them, hot pressing is the key, and cold pressing is the auxiliary. During hot pressing, under high temperature and high pressure, the resin in the prepreg melts and flows to fill the core pattern, after which the resin gels to bond the layers together.

The realization of this process mainly depends on the unique state transition process of the resin (at high temperature, the resin will realize the change of “A-order → B-order → C-order”, and the change is irreversible).

Under normal circumstances, only high multi-layer boards (layers ≥ 3 layers) will use the lamination process, and the core of the lamination method is to gradually increase the layers through multiple lamination, thereby producing high-precision PCBs (such as : HDI).

The complete process flow of the bonding process

1. Brown oxide

Through chemical treatment, an oxide layer is produced on the inner copper surface, and the copper surface is roughened to increase the bonding force.

2. Lay up and rivetpcb layers

Align the PP sheet and the inner layer, and fix them together with a riveting machine (or a hot melt machine).

3. Pressing

The auxiliary materials, (copper foil), (PP sheet), and pre-stacked components (core board) are fed into the press through the automatic reflow line, and the layers are bonded as a whole.

4. Treatment after pressing

The laminated board is processed in order to continue production. Among them, the X-ray inspection layer deviation and the milling target hole are the most important part.

Dec. 20, 2019

Dec. 20, 2019