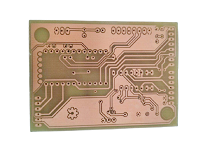

LDI processing requires a circuit board with a photosensitive surface under a computer-controlled laser. The computer scans the plate surface into a raster image. Match the raster image with the pre loaded CAD / CAM design file, which contains the specifications of the image required for the circuit board, and the laser is used to generate the image directly on the circuit board.

The desired image has now become a problem of updating the design file, which can be done more consistently and economically than the traditional film method.

Traditional photo processing requires multiple steps to create a photographic tool for generating images on a PCB. Over the years, this has brought many challenges to PCB manufacturers.

LDI exposure machine has many advantages:

1) Past photo film problems have led to imperfect images because they are vulnerable to temperature or humidity fluctuations. Laser images can produce more accurate and consistent images and eliminate any film related defects.

2) Laser imaging provides precise positioning and improved resolution. Image lines, space and alignment are more accurate.

3) The film method requires a temperature and humidity controlled environment in order to provide the most accurate image transmission for the image. LDI reduces the influence of the environment on the resulting image and eliminates the influence of light refraction inherent in photo processing technology.

4) LDI exposure machine is easier to realize automatic operation, saves labor cost, greatly improves product quality and avoids defective rate.

Oct. 10, 2020

Oct. 10, 2020