Printed circuit manufacturers hope to select dry films with good performance to ensure the quality of printed boards, stabilize production and improve benefits. In recent years, with the rapid development of electronic industry, the precision density of printed boards has been continuously improved. In order to meet the needs of printed board production, new dry film products have been introduced, and the performance and quality have been greatly improved.

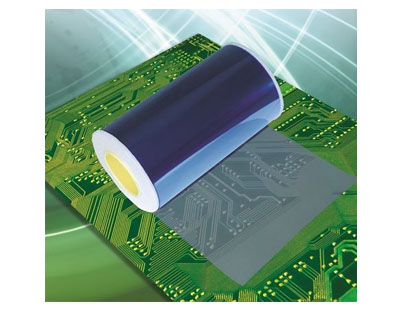

When applying the dry film, first peel off the polyethylene protective film from the dry film, and then paste the dry film resist on the copper-clad foil under the condition of heating and pressure.The resist layer in the dry film softens after heating and the fluidity increases. The film is pasted with the help of the pressure of the hot pressing roller and the action of the binder in the resist.The film pasting is usually completed on the film pasting machine. There are many models of film pasting machine, but the basic structure is roughly the same. Generally, the film can be pasted continuously or single.During continuous film coating, pay attention to align the upper and lower dry film feeding rollers when loading the dry film. Generally, the size of the film shall be slightly smaller than the plate surface to prevent the resist from sticking to the hot pressing roller. Continuous film coating has high production efficiency and is suitable for mass production.The three elements to be mastered during film pasting are pressure, temperature and transmission speed.

Pressure: for the newly installed film applicator, first adjust the upper and lower hot pressing rollers to be axially parallel, and then adjust the pressure by gradually increasing the pressure according to the thickness of the printed board to make the dry film easy to stick, firm and free from wrinkles. Generally, it can be fixed after the pressure is adjusted. If the thickness difference of the produced circuit board is too large, it needs to be adjusted. Generally, the line pressure is 0.5-0.6kg/cm.

Temperature: it varies slightly according to the type, performance, ambient temperature and humidity of the dry film. If the film is coated dry and the ambient temperature is low, the film temperature should be higher when the humidity is small, otherwise it can be lower. A good and stable environment and intact equipment in the darkroom are a good guarantee for the film.Generally, if the coating temperature is too high, the dry film image will become brittle, resulting in poor plating resistance, too low coating temperature, weak adhesion between the dry film and the copper surface, and the film is easy to warp or even fall off in the process of development or electroplating. Generally, the film temperature is controlled at about 100 ℃.

Transmission speed: it is related to the film temperature. If the temperature is high, the transmission speed can be faster, and if the temperature is low, the transmission speed will be slow. Generally, the transmission speed is 0.9 ~ 1.8 m / min.

In order to adapt to the production of printed boards with fine wires, a wet film pasting process is developed. This process uses a special film pasting machine to form a layer of water film on the surface of copper foil before pasting the dry film. The function of the water film is to improve the fluidity of the dry film;Remove air bubbles trapped on scratches, sand holes, pits and fabric depressions;In the process of heating and pressing the film, water increases the viscosity of photoresist, which can greatly improve the adhesion between dry film and substrate, so as to improve the qualified rate of making fine wires.The qualified rate of fine wire can be increased by 1 ~ 9%.

Photosensitivity includes photosensitive speed, exposure time tolerance and deep exposure.Photosensitive speed refers to the amount of light energy required for photoresist to polymerize monomer to form polymer with certain corrosion resistance under UV irradiation.When the light source intensity and lamp distance are fixed, the photosensitive speed is expressed as the length of exposure time. Short exposure time means fast photosensitive speed. Considering improving production efficiency and ensuring the accuracy of printed board, the dry film with fast photosensitive speed should be selected.

After the dry film is exposed for a period of time, after development, all or most of the photoresist layer has polymerized. Generally speaking, the formed image can be used. This time is called the minimum exposure time.The exposure time is extended to make the photoresist polymerize more thoroughly, and the image size obtained after development is still consistent with the image size of the base plate. This time is called the maximum exposure time.Generally, the optimal exposure time of dry film is between the minimum exposure time and the maximum exposure time.The ratio of maximum exposure time to minimum exposure time is called exposure time tolerance.

The deep exposure of dry film is very important.During exposure, the light energy is reduced by passing through the resist layer and scattering effect.If the light transmittance of the resist layer is not good, when the resist layer is thick, if the exposure of the upper layer is appropriate, the lower layer may not react. The uneven edge of the resist layer after development will affect the accuracy and resolution of the image. In serious cases, the resist layer is prone to warping and falling off.In order to make the lower layer polymerize, the exposure must be increased, and the upper layer may be overexposed.

The development of dry film refers to the image effect obtained after the dry film is pasted, exposed and developed according to the best working state, that is, the circuit image shall be clear, and the unexposed part shall be removed clean without residual glue.The anti-corrosion layer left on the plate surface after exposure shall be smooth and solid.The development resistance of the dry film refers to the degree of over development resistance of the exposed dry film, that is, the degree that the development time can exceed. The development resistance reflects the tolerance of the development process.The development and development resistance of dry film directly affect the quality of printed board.Poor development of dry film will bring difficulties to etching. In the pattern electroplating process, poor development will produce defects such as plating failure or poor coating adhesion.The development resistance of dry film is poor. In case of excessive development, problems such as dry film falling off and electroplating infiltration will occur.When the above defects are serious, the printed board will be scrapped.

The so-called resolution refers to the number of lines or spacing that can be formed by dry film resist within a distance of 1mm. The resolution can also be expressed by the absolute size of lines or spacing.The resolution of dry film is related to the thickness of resist and polyester film.The thicker the resist film, the lower the resolution.When the light is exposed to the dry film through the photographic plate and polyester film, due to the scattering effect of polyester film on the light, the light side shoots, which reduces the resolution of the dry film. The thicker the polyester film, the more serious the light side shoots, and the lower the resolution.The minimum parallel line width that can usually be distinguished, the primary index is less than 0.1mm, and the secondary index is less than or equal to 0.15mm.

The dry film resist layer after photopolymerization shall be resistant to the etching of ferric chloride etching solution, ammonium persulfate etching solution, acid copper chloride etching solution and sulfuric acid hydrogen peroxide etching solution.In the above etching solution, when the temperature is 50-55 ℃, the dry film surface shall be free of hair, leakage, warping and falling off.

In acidic bright copper plating, fluoroborate ordinary tin lead alloy, fluoroborate bright tin lead alloy and various pretreatment solutions for the above electroplating, the polymerized film corrosion resistant layer shall be free of surface hair, infiltration plating, warping and falling off.After etching and electroplating, the exposed dry film can be removed in strong alkali solution. Generally, 3 ~ 5% sodium hydroxide solution is used, heated to about 60 ℃, and removed by mechanical spraying or immersion. The faster the film removal speed is, the more conducive to improving the production efficiency.The best form of membrane removal is flake stripping, and the stripped fragments are removed through the filter screen, which is not only conducive to the service life of the membrane removal solution, but also reduce the blockage of the nozzle.Generally, in 3 ~ 5% (weight ratio) sodium hydroxide solution, the liquid temperature is 60 ~ 10 ℃, the primary index is the film removal time of 30 ~ 75 seconds, the secondary index is the film removal time of 60 ~ 150 seconds, and there is no residual glue after film removal.

During storage, the dry film may become brittle due to the volatilization of solvent, may produce thermal polymerization due to the influence of ambient temperature, or may cause uneven thickness due to local flow of resist, that is, the so-called cold flow, which seriously affect the use of dry film.Therefore, it is very important to store dry film in a good environment.The dry film shall be stored in a cool and clean room to prevent storage with chemicals and radioactive substances.The storage conditions are: yellow light area, the temperature is lower than 27 ℃ (5 ~ 21 ℃ is the best), and the relative humidity is about 50%.The storage period shall be no more than six months from the date of delivery. Those who pass the inspection beyond the storage period can still be used.Damp, heat, mechanical damage and direct sunlight shall be avoided during storage and transportation.

In order to avoid missed exposure and re exposure during production operation, the color of dry film should change significantly before and after exposure, which is the discoloration performance of dry film.When used for mask etching, the dry film is required to have sufficient flexibility to withstand the impact of liquid pressure in the development process and etching process without cracking, which is the masking performance of the dry film.

May. 19, 2021

May. 19, 2021