HASL process

1. The purpose of the process

Tin spraying, also known as hot air solder leveling (HASL), is to coat a layer of tin-lead alloy on the copper surface to prevent oxidation of the copper surface and provide a good soldering base for the subsequent assembly process.

The basic process of tin spraying is that the solder pads form a copper-tin alloy (IMC) with high temperature tin through flux, and then the solder pads are flattened by high temperature and high pressure gas.

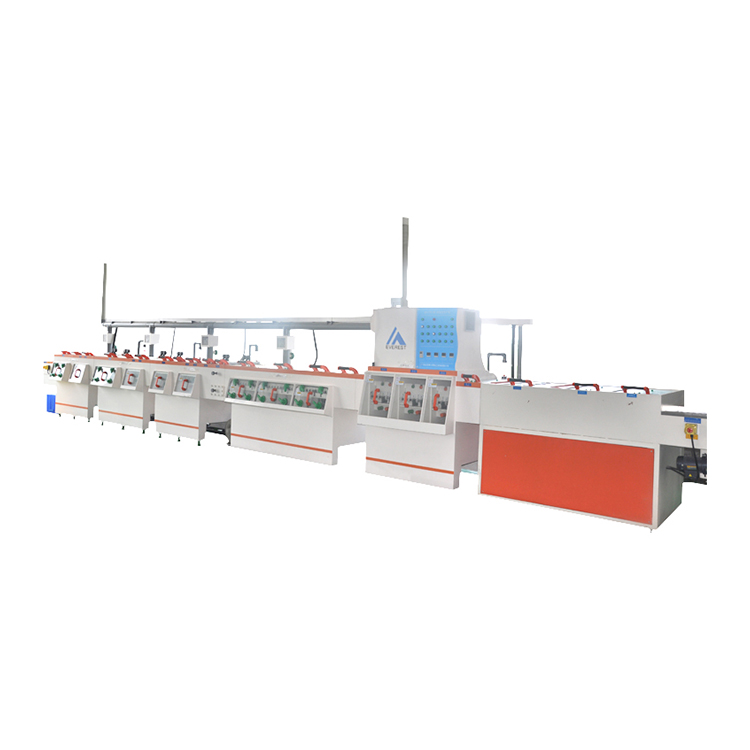

2. HASL process

Coat red glue→cold reel→bake board→hot reel→coat red glue→cold reel→bake board→hot reel→load board→micro etch→rinse→dry board→preheat→rosin→tin spraying→floating bed→hot water rinse → Grind and clean the board → rinse→ dry board → unload

3. Purpose of each process

1) Pre-treatment: Obtain clean, fresh pads.

2) Preheating: Preheating the PCB can shorten the tin immersion time, reduce thermal shock, reduce the temperature drop of the tin furnace, avoid hole plugs or small holes, which is conducive to the faster formation of IMC and tinning. The preheat temperature is generally 170-200°F, too high, it is easy to make the Flux evaporate; too low, the condensed water sprayed tin in the hole will not be bright or tinned.

3) The role of flux or rosin machine

a. Clean the copper surface, reduce the cohesion of tin and lead, and make the pads flat.

b. The flux is slightly acidic, water-soluble, low corrosive, and easy to clean.

c. The heat transfer medium makes the molten tin and the copper surface quickly form a copper-tin alloy.

4) The tin furnace and the air knife are the key parts of the machine. Their functions are:

Coating solder and leveling the solder pads;

Floating a layer of high-temperature oil on the surface of the tin-lead liquid to prevent oxidation of the tin liquid and increase lubrication; Reel)

to avoid contact marks on the board surface, the temperature control of the tin liquid is very strict, if it is too high, it is easy to throw green oil or burst the board, and if it is too low, it is easy to cause rough tin surface and bridges. Wind pressure, wind temperature, wind knife angle, and Andante speed are also strictly controlled according to different situations.

5) The role of the air floating bed: to cool the board and avoid contact marks on the solder pads.

6) Post-processing: cleaning residual rosin, hot oil, floating tin slag

May. 13, 2022

May. 13, 2022