At present, there are many kinds of inks in the market. PCB inks are mainly divided into circuit inks, solder resist inks and character inks.

1. circuit ink

As a barrier to prevent corrosion of the circuit, it protects the circuit during etching. It is generally liquid photosensitive. There are acid corrosion resistance and alkali corrosion resistance. Alkali resistance is more expensive. This layer of ink should be dissolved with alkali after corrosion out of the line.

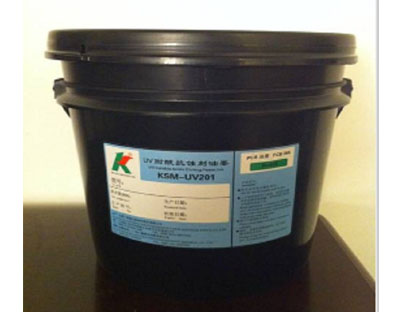

2. Solder resist ink

It is painted on the line after the line is finished to protect the line. There are liquid photosensitive, heat curing and ultraviolet hardening. The pad is reserved on the board to facilitate the welding of components and play the role of insulation and anti-oxidation.

3. Legend ink

It is used to mark the surface of the board, such as the symbol of components. It is generally white.

In fact, there are other inks, such as peelable adhesive ink, which protects the parts that do not need to be treated during copper plating or surface treatment, and then can be torn off; Silver paste ink and so on. The above is the general type of PCB ink.

Characteristics of PCB ink:

1. Viscosity and thixotropy

In the manufacturing process of printed circuit board, screen printing is one of the indispensable and important processes. In order to obtain the fidelity of image reproduction, the ink must have good viscosity and suitable thixotropy. The so-called viscosity is the internal friction of the liquid, which means the friction exerted by the inner liquid when one layer of liquid slides on another layer of liquid under the action of external force. The mechanical resistance encountered by the inner sliding of thick liquid is large, and the resistance of thinner liquid is small. The unit of viscosity is poise. In particular, it should be pointed out that the temperature has an obvious effect on the viscosity.

Thixotropy is a physical property of a liquid, that is, its viscosity decreases under stirring and quickly returns to its original viscosity after standing. By stirring, the thixotropic effect lasts for a long time, enough to reconstruct its internal structure. In order to achieve high-quality screen printing effect, the thixotropy of ink is very important. Especially in the scraper process, the ink is stirred to make it liquid. This function speeds up the speed of ink passing through the mesh and promotes the ink separated by the original mesh line to be evenly connected into one. Once the scraper stops moving and the ink returns to a static state, its viscosity will quickly return to the original required data.

2. Fineness

Pigments and mineral fillers are generally solid. After fine grinding, their particle size does not exceed 4 / 5 microns, and form a homogeneous flow state in solid form. Therefore, it is very important to require ink to have fineness.

Precautions for using PCB ink:

According to the actual experience of most manufacturers in the use of ink, the use of ink must refer to the following provisions:

1. In any case, the temperature of the ink must be kept below 20-25 ℃, and the temperature change cannot be too large, otherwise it will affect the viscosity of the ink and the quality and effect of screen printing.

Especially when the ink is stored outdoors or at different temperatures, it must be placed at the ambient temperature for several days before reuse, or the ink barrel can reach the appropriate operating temperature. This is because the use of cold ink will cause screen printing failure, causing unnecessary trouble. Therefore, to maintain the quality of the ink, it is best to store it under the process conditions of normal temperature.

2. The ink must be fully and carefully stirred manually or mechanically before use. If air enters the ink, let it stand for a period of time. If dilution is required, mix well first, and then test its viscosity. The ink bucket must be sealed immediately after use. At the same time, never put the ink on the screen back into the ink bucket and mix it with unused ink.

3. It is best to clean the net with mutually suitable cleaning agents, which should be very thorough and clean. When cleaning again, it is best to use clean solvent.

4. When drying the ink, it must be carried out in a device with a good exhaust system.

5. To maintain the operation conditions, screen printing shall be carried out at the operation site meeting the process and technical requirements.

What is the role of PCB ink in PCB manufacturing process:

The ink plays a role in protecting the copper foil in the production, so that the copper skin is not exposed, which will affect the subsequent processes. There are photosensitive ink, carbon oil and silver oil, and both carbon oil and silver oil have conductivity. The commonly used ink colors are white, green, black, blue, red and yellow.

May. 18, 2021

May. 18, 2021