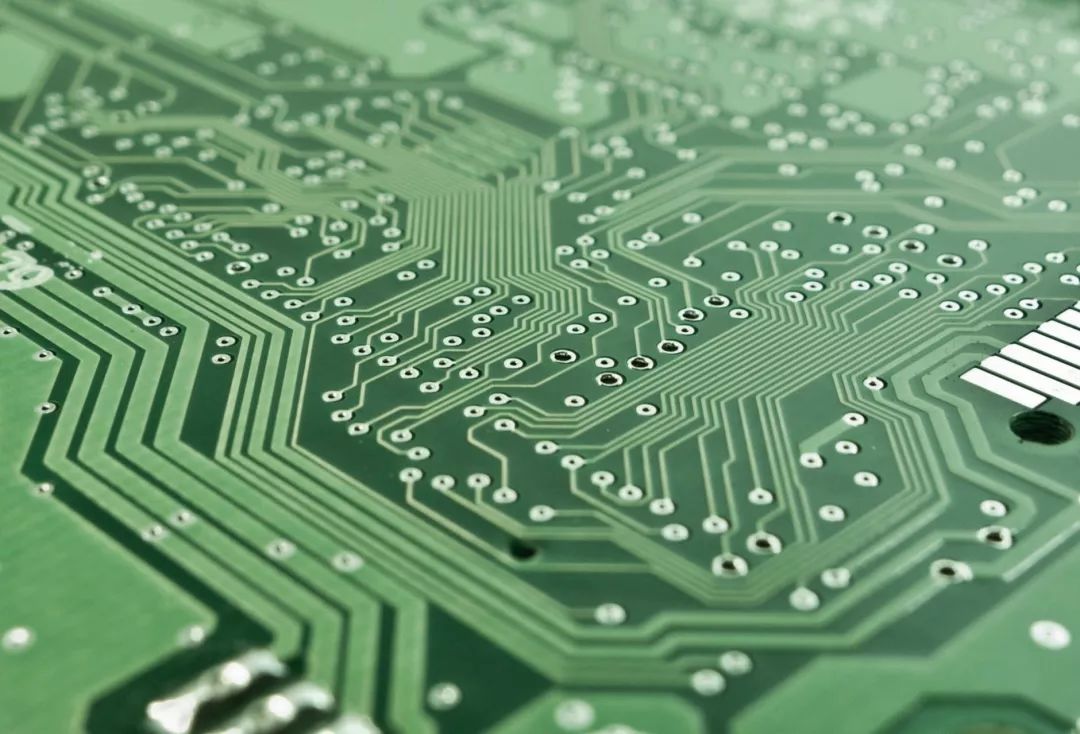

UV exposure machine is an essential equipment for modern PCB manufacturing. In the PCB manufacturing process, one of the most key processes is to transfer the negative image to the copper foil substrate. First, a layer of photosensitive material (such as liquid photosensitive adhesive, photosensitive resist dry film, etc.) is coated on the substrate, and then the photosensitive material coated on the substrate is irradiated to change its solubility. The resin of the non photosensitive part is not polymerized and dissolved under the action of the developer, and the resin of the photosensitive part remains on the substrate to form an image. This process is exposure, That is, the process completed by the exposure machine in the production of printed circuit board.

The main structures of UV exposure machine are:

Light source system, transmission system, vacuum system, temperature control system, electric control system, water control system, control system, etc.

Precautions for UV exposure machine:

1. Do not insert the hand drawn circuit diagram until it is dry.

2. Please use 50% industrial alcohol for cleaning, and do not use chemical solvents.

3. Before the air extraction motor acts, please confirm that the inner tenon is locked.

4. Check the circuit diagram for exposure. Facing the light source, the line part must be opaque. If there is light transmission, it can be supplemented with a black oily signature pen.

5. Never squeeze the inner plastic film and circuit board, just gently remove the residual air with your fingers.

6. After use, please remember to lock the inner tenon and then cover the outer cover.

7. Please remember to take out the circuit diagram after use.

Oct. 10, 2020

Oct. 10, 2020