High-speed motorized spindle is one of the core components of the cutting, high-speed motorized spindle used in the cutting for a long time and high load usually appears all kinds of faults, so what are the common cutting spindle faults? And how to fix them?

1, The spindle noise and vibration of the cutting:

Cause analysis: Spindle bearings or other parts damaged caused by the improper assembly, the precision of the bearing is low or poor stability, poor alignment of the stator and rotor, uneven air gap between the stator and rotor, shaft parts manufacturing precision is low or deformation destroyed the balance precision, after long-term use of preloading load is too small or spring mounted in place even rupture, cage rotor faults or poor contact, Poor rigidity and low precision of grinding wheel connecting rod.

Treatment methods: Select better bearings, modify the coaxiality of stator and rotor, check the accuracy of the main parts such as shell, rotating shaft, rotor and big cover, increase the preload, reassemble the motorized spindle, select the grinding wheel connecting rod with good rigidity and high precision, ensure the normal and stable operation of the motorized spindle.

2, The main shaft of the cutting is stuck and cannot rotate:

Cause analysis: the bearing in the spindle is worn, blocked by debris, resulting in bearing stuck; The clearance between the front and rear dust rings is blocked by foreign objects.

Treatment: the spindle needs to be sent back for maintenance.

3, The chuck can not be locked, resulting in the knife drop, broken knife:

Cause analysis: the front cone of the rotor is damaged, and the surface of the chuck is deformed and damaged.

Solution: please send the spindle back to the conical surface for grinding, the damaged collet can not continue to use.

4, The spindle temperature is too high in the process of use:

Cause analysis: the main shaft has been used for a long time without proper cooling measures; Bearing damage.

Treatment: do a good job of spindle cooling measures, it is recommended to use water cooler and cooling fixture for spindle cooling; Send the spindle back to our company for disassembly and maintenance.

5, The spindle of the cutting is blocked, but the frequency converter shows power output:

Cause analysis: The possible cause is phase voltage imbalance.

Treatment: check whether the spindle and drive line, drive line and frequency converter connection is good.

6, The main shaft of the cuttingstops running and cannot be started:

Cause analysis: The spindle stator coil may be burned out, or the coil insulation paint melts. Check the frequency converter fault information, whether the frequency converter brake.

Treatment method: First of all, use a multimeter to measure the resistance value between the UVW three pins of the spindle back socket is balanced; Then check the use of the environment, whether the use of filter and pressure regulating device for sealing gas filtering and pressure regulating; Check frequency converter parameter Settings and adjust frequency converter parameters. If the resistance is not balanced, it can be determined that the stator coil is burned; Send the spindle back for servicing.

7. It is difficult to start the spindle of the cutting:

Cause analysis: the power plug is not properly inserted, the contact is bad or not connected, the power supply is not enough or does not match with the motorized spindle, the inverter starting protection is not adjusted to the optimal value, the power supply phase is missing or the contactor contact is bad, which will lead to the motorized spindle starting difficulty. The pre-load of the bearing in the motorized spindle is too large and the rubbing between the parts will also lead to its starting difficulty, but in most cases, the reasons for its starting difficulty are: the lead wire of the motor stator in the motorized spindle is wrong, the air gap between the stator and the rotor is too small and the stator winding is damaged.

Treatment: first check the voltage, current and power of the power supply, check whether the power supply is normal, readjust the frequency converter according to the electrical parameters of the motorized spindle, and then check the insulation of the stator winding to the ground and the balance state of the three-phase winding. Once the fault is found, repair it immediately. If the air gap between the stator and rotor is too small, grind the outer diameter of the rotor to maintain the design value of the stator and rotor gap. If there is friction between parts, grind the outer diameters of parts to make sure there is sufficient clearance between them. Modifying the preload set value can also improve the motorized spindle starting condition. Therefore, when the motorized spindle is difficult to start, specific solutions should be found for equipment.

8, The machining accuracy is poor:

Cause analysis: bearing accuracy is low, spindle accuracy is poor, artificial damage or long time work makes spindle accuracy loss, the front end bearing seat and bearing are too loose, the pre-load is too small or parts are stuck, the front and rear nuts are loose, the shaft appears to move, grinding wheel connecting rod quality is poor.

Treatment method: select better bearings, reassemble them, plated hard chrome on the seat hole and spindle, regrind them to the required accuracy, increase the pre-tightening force, lock the front and rear nuts, and lock them with fixed locking screws, and select the grinding wheel connecting rod with good rigidity and high precision.

9,Slow down or speed is not stable:

Cause analysis: The power supply voltage is too low, does not match the electrical parameters, the power is small, and the rotor cage strip is broken or in bad contact.

Treatment method: First check whether the power output, frequency, voltage and power match with the motorized spindle. If the power of the motorized spindle is small, select a high-power motorized spindle that meets the requirements of the working condition, check the quality of the cage strip, and choose the motorized spindle with a larger capacity.

10, Bearing continuous burning loss:

Cause analysis: poor lubrication, high speed, too small or too large preloading, too much load.

Treatment: replace grease or check the quality of oil mist, check the oil supply condition of oil channel, measure the rotational speed, adjust the frequency converter to ensure the normal operation of motorized spindle, detect and adjust the preloading load, so that it can reach the best value.

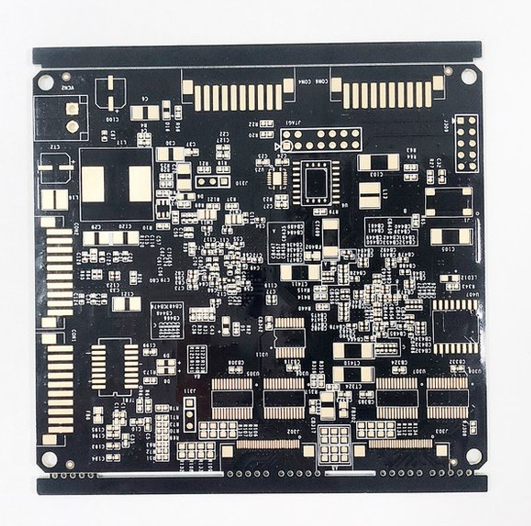

Pay attention to the three maintenance of PCB cutting machine:

1, PCB cutting for the operation of the cause of the problem: the battery is not enough power, the connection between the battery and the starting motor is disconnected. The phenomenon of oxidation of battery or connection clip; The electromagnetic switch and the two large terminal contact is not good or the guide plate is seriously ablated; The brush is worn, broken or stuck in the brush frame; Oil stains or severe ablations of rectifiers between brush rectifiers.

2, part of the winding short circuit or circuit break: there are three reasons will appear this situation, one is the armature winding or commutator piece welding phenomenon, two is the bearing or copper sleeve wear leading to the rotor sweep chamber, three is in the installation of the position of the four brush is wrong or the new shaft sleeve clearance is too large. The time and space rotation of PCB board cutting startup: the fork is not installed correctly. The sliding column device of the fork makes it impossible for the motor gear to rotate with the fork in the moving bushing.

3, The motor will rotate when the PCB cutting starts. The gap between the electromagnetic switch core and the push rod of the contact plate is too large to cause the one-way clutch to slip and not drive the flywheel gear ring to rotate. Once the starter gear is seriously worn, it will not fit well with the flywheel gear ring. Electromagnetic switch often suction often open, refers to after pressing the start switch, the iron core of the electromagnetic switch just sucked up will immediately off, off will be sucked up again, and then immediately off, not up to the effect of starting the initiator 1. A common cause of this phenomenon is persistent coil disconnection.

Jan. 07, 2023

Jan. 07, 2023