What are dry film and wet film?

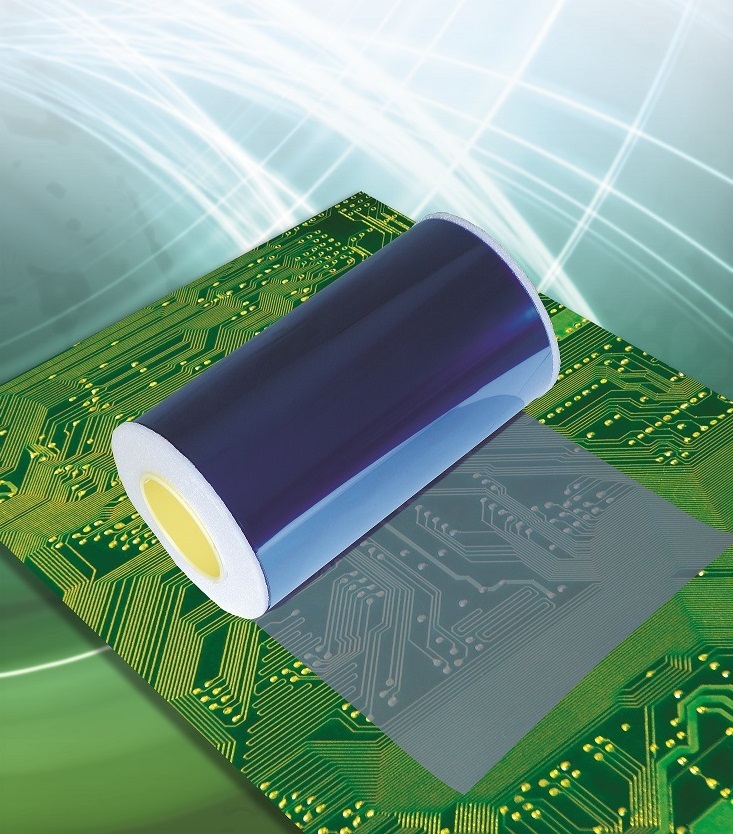

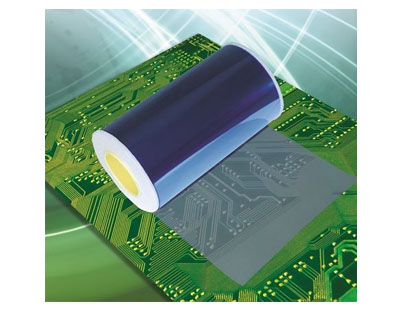

PCB dry film and wet film refer to the raw materials used for making circuits. Dry film is a polymer compound. It can produce a polymerization reaction after ultraviolet irradiation to form a stable material attached to the board surface, so as to prevent electroplating and etching.

Wet film is a kind of photosensitive ink, which is sensitive to UV line and can be cured by UV.

When to use dry film and when to use wet film ?

The functions of dry film and wet film are basically similar, but if the surface is not flat or it is not necessary to establish a thick height or a very thin film thickness, the manufacturer can consider using wet film.

If it is a circuit board with holes, the dry film will be more suitable. If the environment is not easy to keep clean, the dry film is also easier to control the quality of operation. Although the materials of wet film are relatively cheap, they are not available everywhere.

In addition to general considerations, consideration should also be given to the needs of the manufacturer’s own operating environment.

Advantages and disadvantages of dry film and wet film

1) Dry film is easy to operate, but the unit price is slightly higher than that of wet film.However, because it is easy to keep clean and does not have to be baked, and the operability is better, it is more advantageous in use.However, for thinner film thickness, especially below 15㎛ thickness, dry film is not easy to do.

In addition, the better filling capacity of the wet film is its advantage, but because there is no protective film, it requires higher exposure energy.

2) At present, the so-called wet film is almost always used in welding paint. As for the application in inner plate, the proportion of wet film is also higher and higher, which is due to the low cost and the gradual improvement of technical maturity.However, in terms of inner plate production, the dry film is easy to operate. In particular, the automatic film applicator can be used for large-scale production. The wet film is cheap, but it is not suitable for the automatic line. In theory, the thin line of the wet film is good, but the wet film also has many other problems.

In general, dry film is better than wet film, convenient and stable. The only disadvantage is that the price is expensive. If I am an engineer, I choose dry film, which has less trouble and convenient to control.

Different views have different advantages and disadvantages, which must be carefully compared by the user in order to obtain a more suitable conclusion.

May. 19, 2021

May. 19, 2021