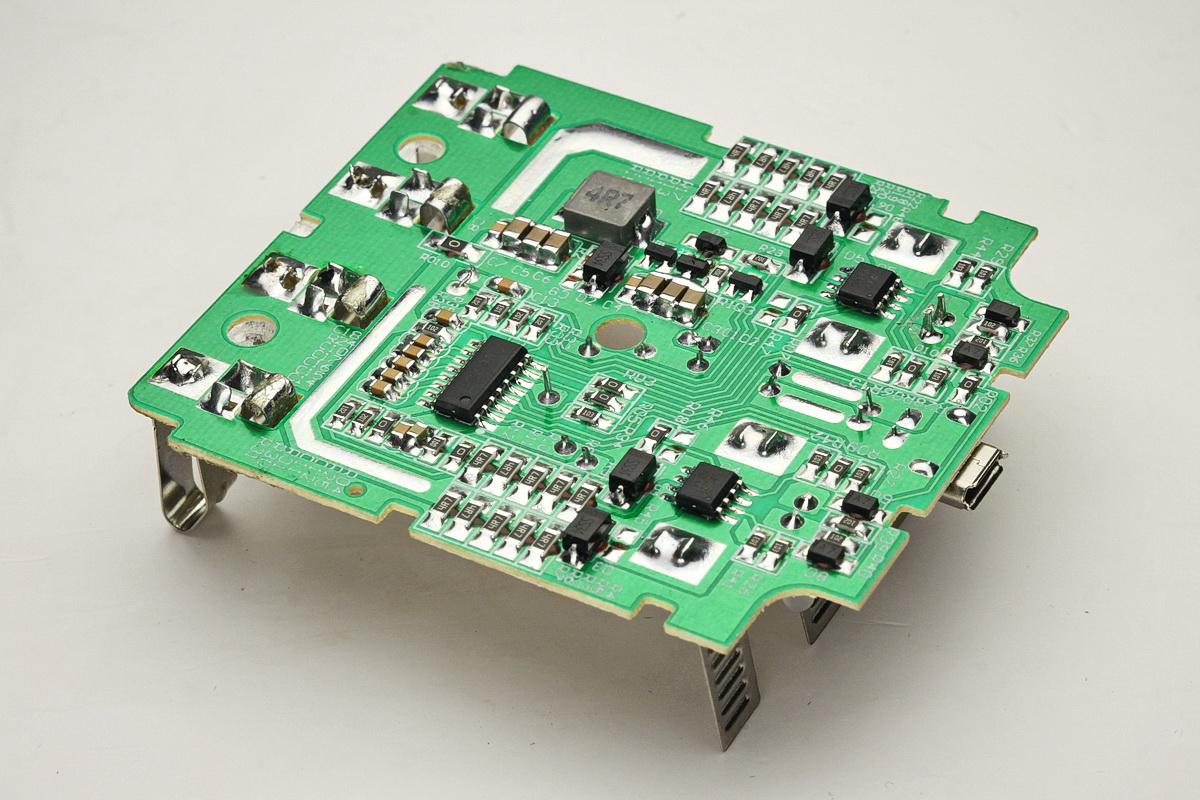

What are the areas of PCB used in our daily life

Because PCBs are used in many different fields, they can be found almost anywhere, from small consumer devices to large machinery. Where are printed circuit boards used? The following are the 10 most common PCB applications in the industry.

1. Medical equipment

With the advancement of technology, the healthcare industry is using more and more PCBs, showing new functions. PCBs play a role in equipment used for diagnosis, monitoring, treatment, etc. Special care must be taken to ensure reliability when producing medical PCBs, because proper functions are essential to the health of patients. In many cases, PCBs must also meet strict hygiene standards, especially those used for implants. The boards used for implants and many other applications (such as emergency room monitors) must also be relatively small. Therefore, many medical PCBs are high-density interconnects or HDIs.

2. Light Emitting Diode

Light-emitting diode (LED) is an increasingly popular lighting technology used in residential and commercial lighting, and in many industries such as automotive, medical, and computer technology. LEDs are favored for their high energy efficiency, long life and compactness. One of the roles that PCB plays in LED applications is to dissipate the heat of the bulb. High temperature will reduce the average life of the LED. Therefore, PCBs used for LEDs are usually made of aluminum, which can transfer heat better than other metals. This eliminates the need for an additional heat sink in the design, which means it can become more compact.

3. Consumer Electronics

The smartphones, computers, and many other consumer products that people use every day require PCBs to function. As we add electronic products to more products, PCBs have become an important part of our daily lives. Manufacturers are producing smaller and smaller smartphones and laptops, which have many advanced features and require small PCBs with a large number of connections. PCBs used in consumer electronics products also require relatively low costs to keep the final product prices low. Manufacturers also need reliable circuit boards because they need their products to perform their intended functions in order to continue their business.

4. Industrial equipment

The use of printed circuit boards in the industrial field varies greatly. Electronic components power many equipment in manufacturing and distribution centers and other types of industrial facilities. PCBs used in the industrial sector usually require extremely high power and are durable enough to withstand the harsh conditions that exist in industrial facilities. The PCB may require rough handling, anti-vibration machinery, extreme temperatures or irritating chemicals. To meet this durability requirement, industrial PCBs can be made of durable metals or heat-resistant materials and thicker than other types of PCBs. Industrial PCB assembly services may include through-hole technology to improve durability.

5. Auto parts

Automobile manufacturers are using more and more electronic components in their vehicles. In the past, PCBs were only used for components such as windshield wipers and headlight switches, but now they have many advanced features that make driving safer and easier. Depending on which part of the car the PCB is used for, it may need to be able to withstand extreme temperatures or vibrations. It is also important that if the safety functions of the car are involved, they must operate reliably. Because of these challenges, manufacturers may use high-temperature laminates, aluminum or copper substrates, or through-hole mounting components. Because they can withstand vibration, they also use rigid-flex PCBs.

6. Aviation Parts

Electronic products used in aerospace applications are similar to the requirements of the automotive industry, but aerospace PCBs may be exposed to harsher conditions. PCB can be used in a variety of aerospace equipment, including airplanes, space shuttles, satellites, and radio communication systems. Aerospace PCB manufacturing requires materials that can withstand large amounts of vibration, extreme temperatures, and other harsh conditions. Certain aviation PCBs even need to be able to operate in outer space and must be very durable. Plates made of lightweight materials such as aluminum can also be used in aerospace. Anodized aluminum can be used to increase oxidation resistance.

7. Marine applications

Various ships and systems rely on PCBs to operate. This includes small vessels, large cargo ships, submarines, communication systems and navigation equipment. PCBs used in maritime applications must also be able to withstand harsh conditions. Offshore PCB manufacturers emphasize reliability, because the normal operation of electronic equipment is essential to the safety of crew and passengers.

8. Safety equipment

Whether it is a home, a business or a government building, many aspects of the security system rely on PCBs. They play more roles in our safety and security than many people realize. The ideal PCB type depends on its specific application, but all PCBs used for safety applications must be reliable because these products must always operate as expected to be effective. Some safety equipment may be used outdoors, and PCBs that can withstand the outdoor environment should be used.

9. Telecommunications equipment

PCB is a key part of the telecommunications industry. They are essential for consumer devices such as smartphones, but they are essential for the infrastructure that enables these devices to work properly. Since many different types of equipment are used in the industry, a wide variety of PCBs are used in the telecommunications industry. Some equipment must be placed in a stable indoor environment, while some infrastructure must withstand outdoor environments including storms and extreme temperatures.

10. Military and defense applications

The military uses PCBs in various applications, including communication equipment, computers, vehicles, guns, etc.

PCBs used in military applications must be very reliable and durable. They may face extreme conditions and may play a role in national security. The military uses materials such as high-temperature laminates, aluminum and copper because of their ability to withstand harsh conditions such as high temperatures. Due to its oxidation resistance, anodized aluminum can be used. Some military printed circuit board applications may also benefit from the enhanced reliability of through-hole technology.