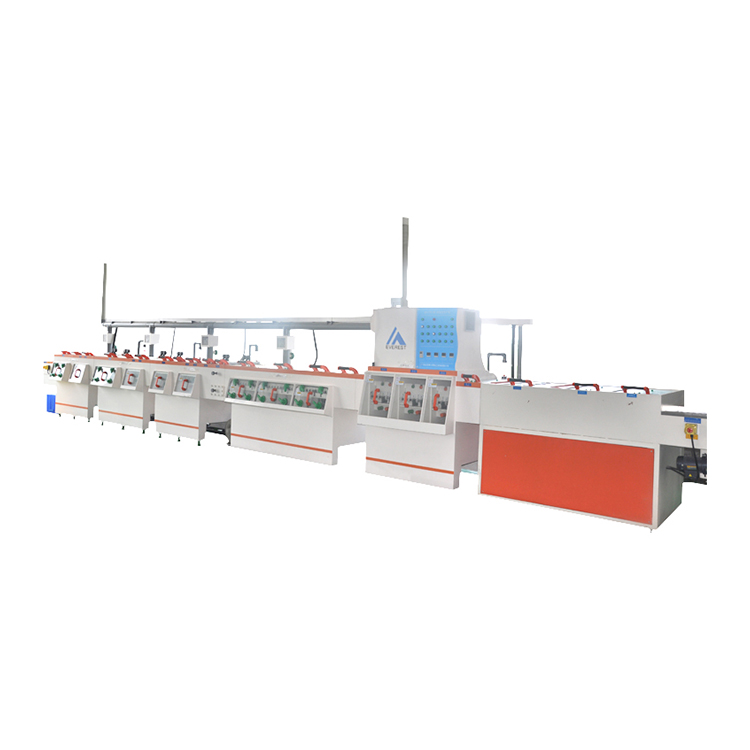

Process flow

feeding→degreasing→pump rinsing→tap water rinsing→micro-etching→pump rinsing→tap water rinsing→pickling→pump rinsing→tap water rinsing→blot up→wind shear→OSP→pump rinsing→pump rinsing→tap water rinsing→blot up→cool air bolt→hot air drying→discharge

Feature

Comprehensive Explanations

1)Spraying system

(1) Degrease , micro-etching, pickling using quick release ,convenient maintenance and cleaning

(2) Rinsing part using PVC small nozzle

2) The filtration system

Using multiple filtration system to protect the pump and spraying nozzle. Especially maintenance, our use can be used repeatedly.

3) Transmission system

(1) Adopts frequency conversion motor, imported PVDF pin gear, to ensure strength, wear resistance, corrosion resistance and transmission uniformity.

(2) With hard wheel structure, smooth surface to ensure smooth delivery, will not scratch.

(3) Wheel base is 40mm.

(4) Main transmission is used the inner and outer structure of a structure. And in the choice of

materials is very unique: imported PVDF material inner sleeve, outer with UPVC material, thus ensuring a more wear-resistant and durable.

(5) The braking system: the general button control, the highly humanized operation, and ensure the high quality and long life.

(6) The tanks are made of tilting Bottom, can drain the tank residue for easy cleaning.

(7) Wire on the top of the machine, safe and beautiful.

(8) Tap water rinsing with solenoid valve and a separate manual switch, and with a flow meter, automatic control spray, and can adjust the amount of water.

(9) The exhaust pipe on the top, make the each part independently and adjustable.

(10) This line is equipped with head and tail are emergency stop switch, so in an

emergency, the full range of rapid braking.

Specification

|

1) Dimension |

11127mmL*1650mmW*1935mmH |

|

2) Working pieces |

600mmL*600mmW(Max) |

|

150mmL*150mmW(Min) |

|

|

0.2mm~3.2mm(thickness) |

|

|

3) Transfer speed |

1~4m/min(adjustable) |

|

4) Working surface high design |

1.8~2.5m/min(adjustable) |

|

5) Transmission surface high |

950±20mm |

|

6) Transmission width |

630mm |

|

7) Diameter of transmission wheel |

Φ40mm |

|

8) Transmission wheel base |

50mm |

|

9) Power supply |

380V/AC/50HZ/38KW |

|

10) Water consumption |

10~20L/min |

|

11)Process flow direction |

from left to right (front) |

|

12)Control system |

button |

|

13)Control box place |

Overhead cabling |

|

14)Waster water pipe |

one drainage pipe |

|

15)Water inlet |

one tap water pipe |

OSP line video

Looking forward to providing you with satisfactory products and services.

info@everest-machinery.com